Business Content

Introduction to Technology | CFRP

Products

Highest Weight Reduction

Automobile

Design, development, prototyping, and manufacturing of parts for SUPER GT vehicles and limited production vehicles. R&D support for next-generation mobile vehicles and show car production.

Motorcycle

Design, development, prototyping and manufacturing of parts for MOTO GP and WSB vehicles.

Aeronautics & Space

Design, development, prototyping, and manufacturing of components related to space observation equipment.

Welfare/Marine

Design, development, prototyping, and manufacturing of parts related to welfare vehicles and marine project equipment.

Sports

Design, development and prototyping of new products in accordance to the requirements of athlete and maker.

Special Development

Design, development and prototyping of parts related to Pro Use and Robot business.

Auto Clave Molding

Prepreg laminates the resin film into the mold. After being placed in an airtight sealed bag, it is pressurized and cured in a clave under reduced pressure and vacuuming.

Merit

- High-temperature, high-pressure, vacuum forming ensures uniform fiber content, resulting in high strength, high durability, and ultra-lightweight molded products.

- Products with complex shapes can be manufactured.

Demerit

- There is a long cycle time due to having multiple processes. In case of mass production, the number of molds needs to be increased depending on the quantity, resulting in high costs.

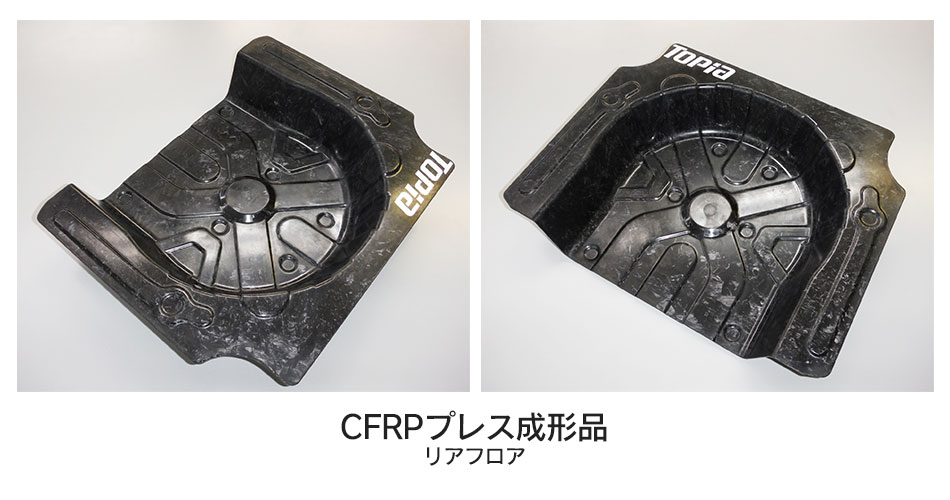

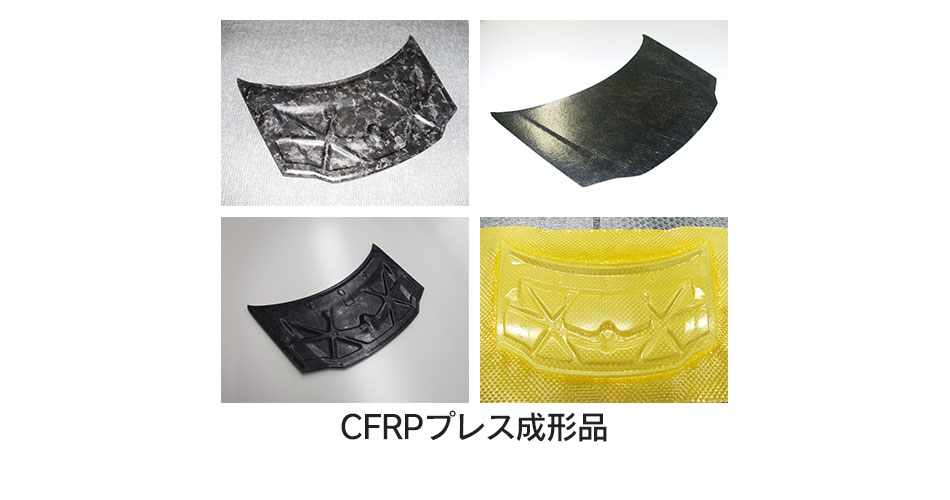

Press Forming

SMC (Sheet Molding Compound) is cured by molding pressure using high-precision airtight molds.

Merit

- Press Forming is available for both thermosetting and thermoplastic materials.

- Compared to hand layup and auto clave molding, the molding cycle is shorter and mass production is higher.

Demerit

- Two types of molds are required for the process: one for pre-foam and the other for the press.

- Restrictions on the degree of freedom of shape. High initial cost and short delivery time.

Multi Material (B Pillar) Molding Technology Development

Aluminum/Carbon integrally molded product

Main Facilities

- CAD Soft(CATIA)

- 2Licenses

- Composite Analysis Soft

- 1License

- Inspection and Measurement Equipment

- Instron Tensile Tester

- Non-destructive Inspection System

- UT(Ultrasonic) / IRT(Active Thermo)

- Cutting Plotter

- 1,200×3,000

1,200×1,800 - Clean Booth

- 9,700×6,000×2,500

[Class100,000Level]

- Auto Clave

- φ1,000×1,300(Small-size)

φ1,500×2,500(Med-size)

φ2,000×5,000(Large-size)

- Oven

- [200℃spec]1,150×2,000×2,000

- IR Heater

- [400℃spec]1,200×1,000

- Material Storage Freezer

- 3,600×2,700×2,500

3,600×1,800×2,400 etc.

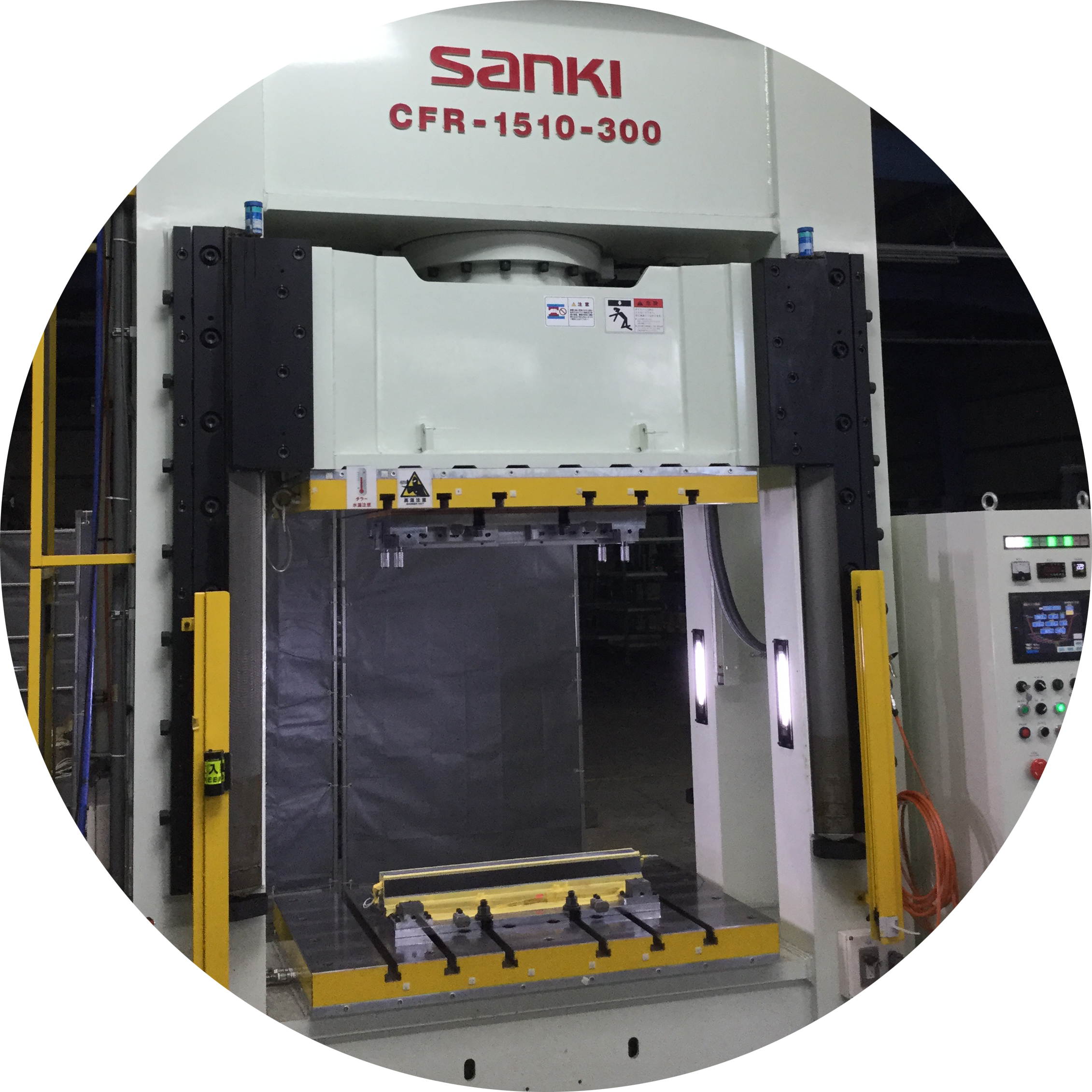

- Hot Press Machine

- 300t/1,500×1,000

1000t/4,000×2,000(*Head office plant)

2000t/3,000×2,000(*Head office plant)